Health Use Case - Supply Chain Management

Supply Chain Management – A large healthcare provider looked to improve their cash flow and their 340B compliance

Situation

The company’s pharmacy team lacked the bandwidth and tools needed to effectively monitor the performance of its site-based teams and purchasing partners. Over the past few years, it had launched a number of programs aimed at closing this gap with inconsistent results. They were confident that optimizing their medication acquisition monitoring process would help reduce the cost of service from their wholesaler while increasing opportunities for tier pricing reduction. The company was also seeking potential savings through the optimization provided by class of trade purchasing and improved tracking and 340B compliance.

Contributing Factors

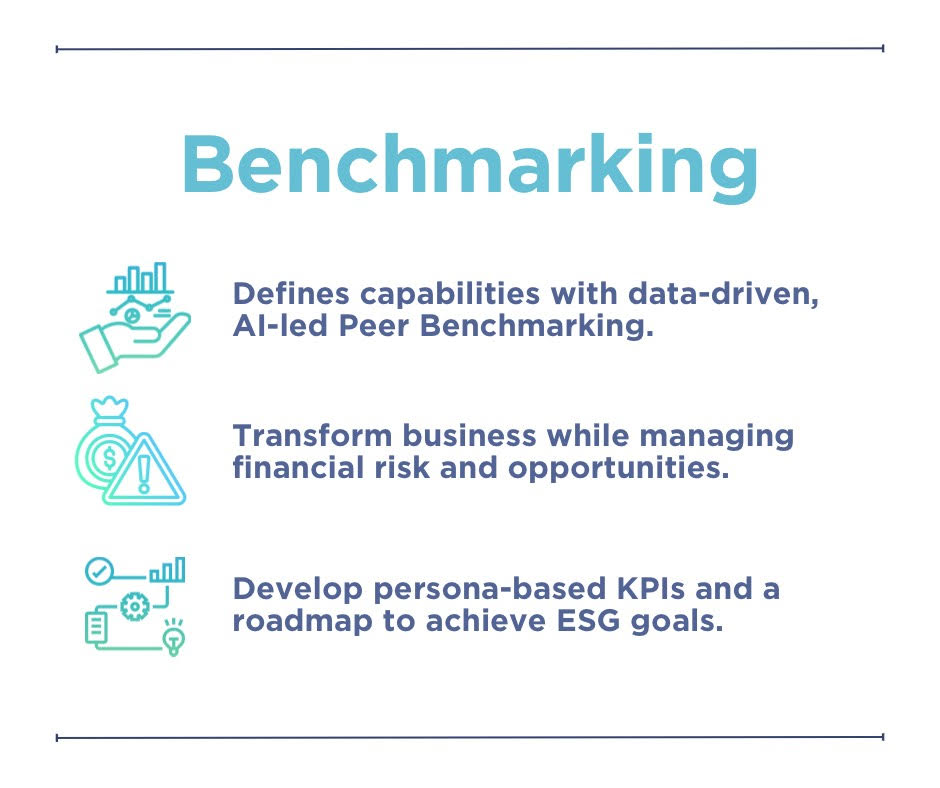

Processes, all conducted manually, were disparate. KPIs were not set correctly. No tracking of inventory sources existed.. Their business model lacked integration between the inpatient and outpatient pharmacy.

Challenges

The organization was struggling to manage 340B compliant inventory movement and, in turn, the cost of their pharmacy supply chain. Also, ineffective management of their pharmacy integration with corporate hospital groups was resulting in critical cost and revenue leakage.

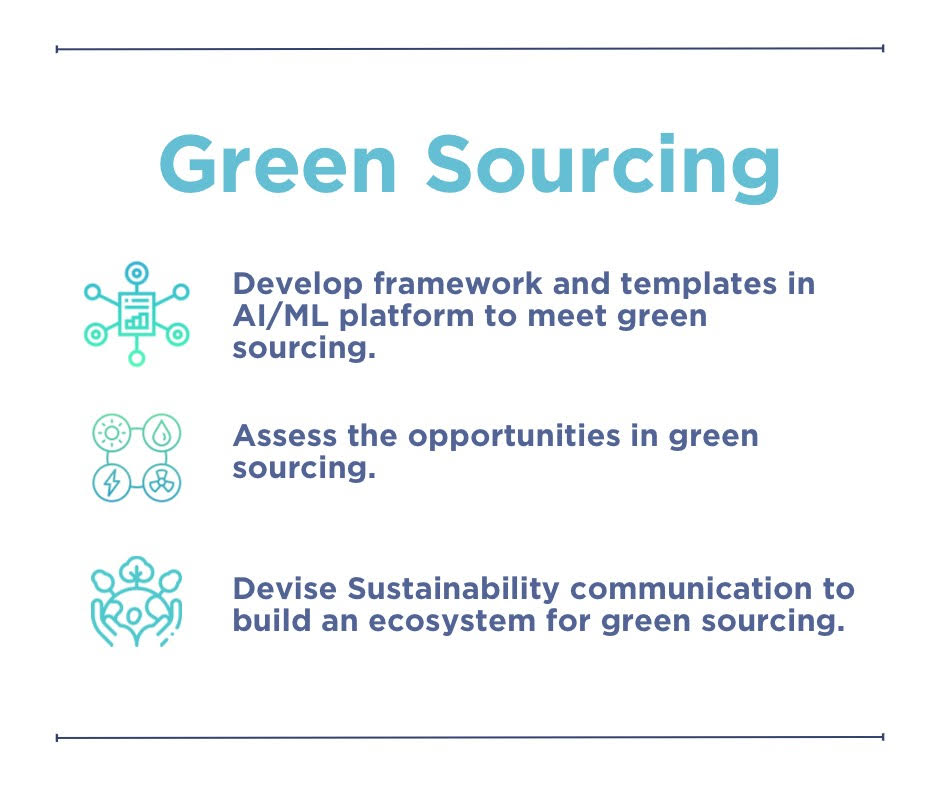

Modularized Solution from Amplo Global Inc.

An AmploFly4.0™-led transformation streamlined the pharmacy supply chain, enhancing company profitability and the overall patient experience. That transformation first focused on planning, procuring, storing, moving and paying for goods and services more efficiently. With increasing sophistication, the focus shifted to increasing effectiveness and responsiveness. The resulting benefits included decreased costs, increased value from suppliers, improved patient care and enhanced employee satisfaction.

Additional Benefits

The organization make more mature with data and hence started predictive analysis as a new normal..