Empowering Supply Chain Intelligence: 360 Insights

| Enhance operations with Supply Chain Intelligence. Real-time data and predictive analytics optimize efficiency, mitigate risks, and drive growth |

The making of the circular supply chain

In an ideal world, sustainability is more than just a marketing buzzword — it is a core tenet of an organization that wants to do more good to the environment than harm. Or at least achieve a net-zero impact by managing to eliminate or recycle 100% of the waste it generates.

This is the very foundation of a circular economy, and it has been described as an economy that is “restorative and regenerative by design”. And in this circular economy, a circular supply chain plays a pivotal role — in fact, without first achieving a restorative supply chain, a circular economy will most likely remain just a pipe dream.

What a circular supply chain is

A circular supply chain is one where organizations reduce waste at every stage, right from design and manufacturing to distribution and fulfilment. This approach shifts away from the standard pattern of produce, use and discard, and instead adopts one where the organization is acutely aware of the impact it is having on sustainability. It looks at the bigger picture and attempts to minimize perturbations to it.

An example of this paradigm shift in thinking is the clothing brand, Dutch aWEARness, which has created a track-and-trace system to follow clothing through its entire lifecycle. Used articles of clothing are returned to the brand, which then repurposes and reuses the materials, thereby drastically reducing waste.

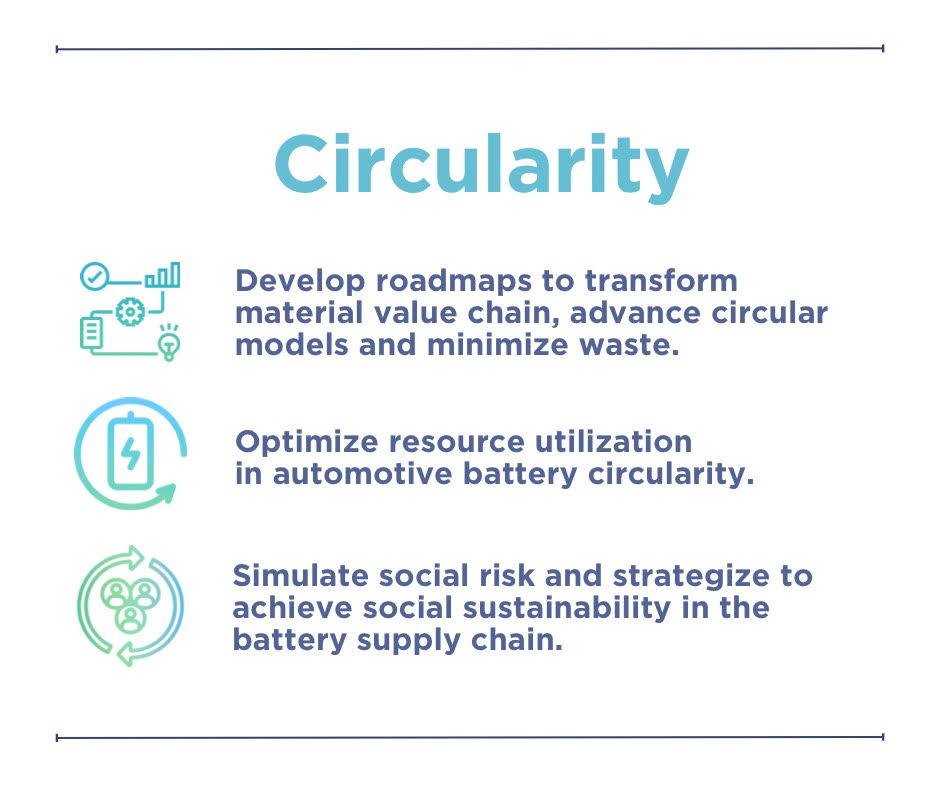

Models for circular supply chain

There are three broad approaches for creating a circular supply chain. In the first, manufacturers can tackle recycling and minimizing waste by offering ‘product as a service’. This allows them to maintain control of the product through its lifespan, and ensures that it is properly disposed of or recycled. The second method would be to incentivize customers to return used products to the manufacturer — for example, trading in old phones when upgrading to a newer model.

The third idea is to do plastic pallet pooling. As iGPS observes, before pooling, used wood shipping pallets accounted for a lot of waste in the supply chain. “The pooling model made it possible for warehouses, manufacturers, and distributors to rent, rather than buy, their pallet supply. These companies no longer had to spend a large amount of money upfront on a pallet fleet of their own, which they would have to manage, maintain, and store.”

Moreover, organizations can take a firm stance to work only with suppliers and vendors that have a robust track record on the sustainability front. “Green practices and circular supply chains go hand in hand, as both focus on reducing waste and ensuring a more efficient use of natural resources,” says the iGPS report.

An intelligent supply chain

The future of the market entails smart solutions that harness the power of Manufacturing 4.0 to reimagine the supply chain, identify and eliminate inefficiencies, and draw insights that help develop and boost sustainability strategy. Anirban Bhattacharyya, Board Member at Amplo Global, observes that technologies like automation, IoT, and advanced analytics are all set to permanently change the way supply chains operate — right from how goods are produced to how they are sold.

Industry 4.0 has created a remarkable opportunity for AI and data analytics to make a circular supply chain a reality. It can do so by reducing waste, optimizing resources, accurately estimating demand and inventory levels, and helping businesses avoid manufacturing in excess quantities. “Given the scope for process improvement within the distribution sector, organizations need robust strategies to effectively estimate their business transformation needs, analyze their operations, and focus on cost management. A mindful overhaul of the company culture also has the potential to make value-chains more productive for all involved and boost efficiency,” adds Bhattacharyya.

Not just a fad

Accenture notes that a circular supply chain holds the potential to change how food, and retail goods are produced, enhancing producer’s incomes and environmental outcomes. Its 2019 edition of CEO study on sustainability found that of 90% of CEOs see sustainability as important to success. These CEOs “acknowledge the opportunity for competitive advantage through leading on environmental, social and governance issues and report real progress, impressive innovation and impact. They also recognize the business community could and should be making a far greater contribution to achieving a sustainable global economy and society by 2030”.

A receptive audience

And it is not just CEOs. Consumers too are warming up to the need for sustainability in the products they buy. Accenture found that more than half of consumers are ready to pay more for sustainable products. 83% believe it is important or extremely important for companies to design products that are meant to be reused or recycled. Nearly three-quarters (72%) of respondents said they are currently buying more environmentally friendly products than they were five years ago, and 81% said they expect to buy more sustainable products over the next five years.

In short, circular supply chains already have a receptive market rooting for it.